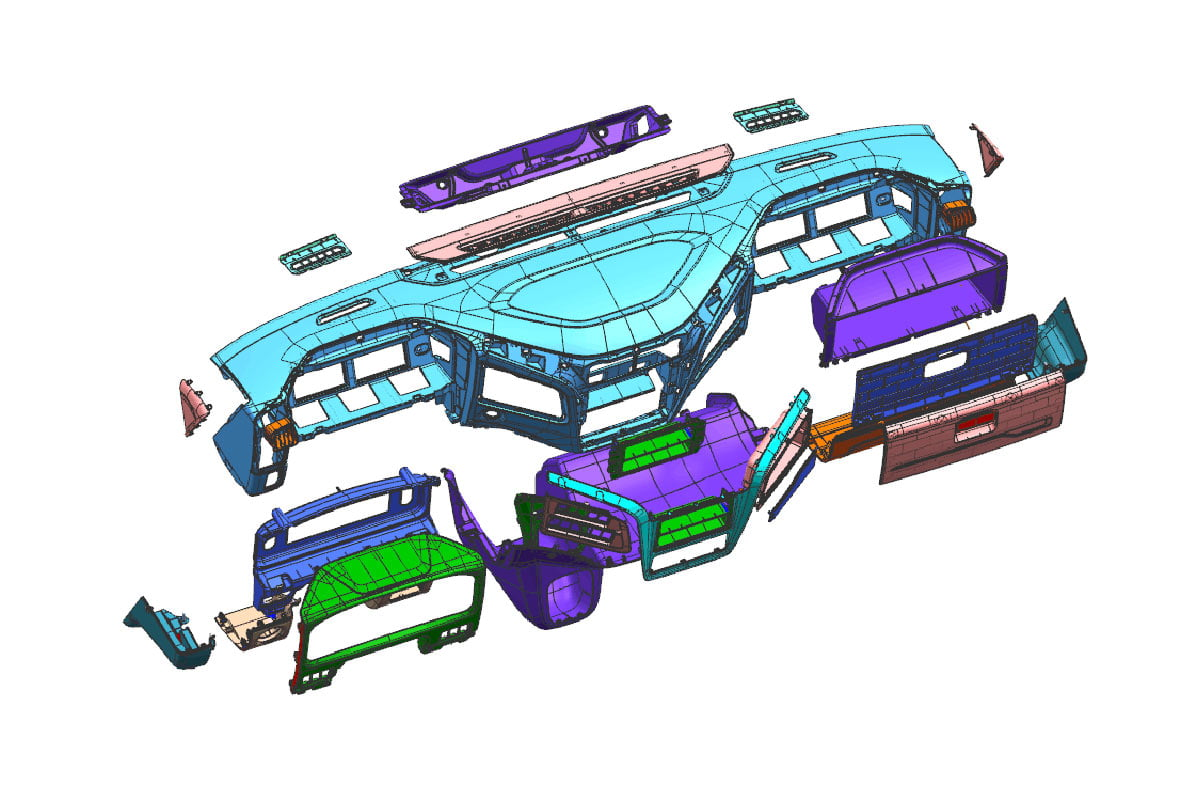

Rapid injection molding is a specialized manufacturing process that enables the quick and cost-effective production of plastic parts and components. It is widely applied in automotive, medical, home appliances, and other industries and emphasizes speed and efficiency to reduce lead times and bring products to market faster. This technique is particularly significant in modern manufacturing for several reasons.

First, it accelerates the product development cycle, allowing companies to prototype and iterate designs rapidly. Second, it enables on-demand production, reducing the need for extensive inventories and minimizing waste. Third, it supports small-batch and customized production, catering to the growing demand for personalized products.

In essence, rapid injection molding streamlines the entire production process, making it a crucial tool for businesses seeking to stay competitive and innovative in today’s fast-paced manufacturing landscape.

How Does Rapid Injection Molding Differs From Traditional Methods?

Rapid plastic injection differs from traditional methods, emphasizing speed and efficiency. Unlike conventional injection molding, which often involves lengthy tooling and setup processes, rapid injection molding utilizes simplified tooling and standardized components, reducing lead times from weeks to days. It also prioritizes quicker design validation through rapid prototyping and iteration, allowing design changes to be implemented more readily.

Additionally, rapid plastic molding is well-suited for lower-volume production runs, making it a cost-effective choice for small batches and custom orders. Overall, its streamlined approach and accelerated production timelines distinguish it from the more time-intensive and costly aspects of traditional injection molding, making it an invaluable tool for modern manufacturing needs.

The Process of Rapid Injection Molding

The method of rapid injection molding involves the following key steps:

- Design and CAD Model:The process begins with creating a 3D computer-aided design (CAD) model of the part or component to be manufactured. This digital model serves as the blueprint for the injection molding process.

- Tooling and Molding:Rapid tooling techniques are employed to create the mold quickly. These molds are typically made from aluminum or other materials suitable for short-run production. Traditional molds made of steel are not necessary, reducing lead times significantly. Afterward, the mold is affixed onto an injection molding apparatus.

- Material Selection and Injection: Plastic material, usually in the form of pellets, is selected based on the requirements of the part. The material is heated and injected into the mold cavity under high pressure. This process ensures the material fills the mold and takes its final shape.

- Cooling and Ejection: The injected material solidifies within the mold. Once the part is fully formed, the mold opens, and the newly manufactured component is ejected.

Advantages of Rapid Injection Molding

- Speed: Rapid injection molding drastically reduces lead times, allowing for the production of parts in days rather than weeks or months. This accelerated timeline is invaluable for meeting tight project schedules and getting products to market faster.

- Cost-Efficiency: By simplifying the tooling and mold-making process, rapid injection molding lowers tooling costs and minimizes the need for expensive, high-volume production molds. This cost-effectiveness is particularly beneficial for small production runs and prototypes.

- Design Flexibility:Rapid injection molding supports design iterations and changes with ease. Adjustments can be made quickly and cost-effectively, ensuring the final product meets design specifications and quality standards.

- Prototyping:This technique is ideal for creating prototypes to test and validate product designs before committing to full-scale production. It allows for refining designs and addressing potential issues early in the development process.

- Low Waste: With the ability to produce smaller quantities and iterate designs efficiently, rapid injection molding reduces material waste, making it a sustainable and environmentally friendly choice in modern manufacturing.

If you are a business seeking high-quality, efficient, and versatile plastic injection molding solutions, WOKA should be your top choice. Our rapid injection molding expertise caters to various industries, offering precision and reliability for automotive, medical, home appliances, 2K molding, electronic, and precision injection moulding products.

Conclusion

Woka, founded in 2005, is a renowned Chinese precision plastic mold manufacturing industry. We boast a state-of-the-art facility equipped with advanced molding, injection, and quality testing equipment, all operated by a dedicated team of highly skilled workers. Regarding plastic injection molding, Woka is synonymous with exceptional quality and expertise.

So, whether you are in the automotive sector requiring precision parts, the medical industry needing stringent quality, or any other industry looking for efficient, top-notch plastic molding, WOKA is the ideal partner for your project.