At WOKA, we take immense pride in our expertise in mold construction. As a leading provider of precision mould solutions, we understand the critical role that mold construction plays in ensuring the quality and performance of injection-molded products. Our skilled team of craftsmen and advanced technologies allow us to deliver exceptional mold construction services that exceed industry standards and customer expectations.

The Thanksgiving of Precision: Optimal Mold Design and Engineering

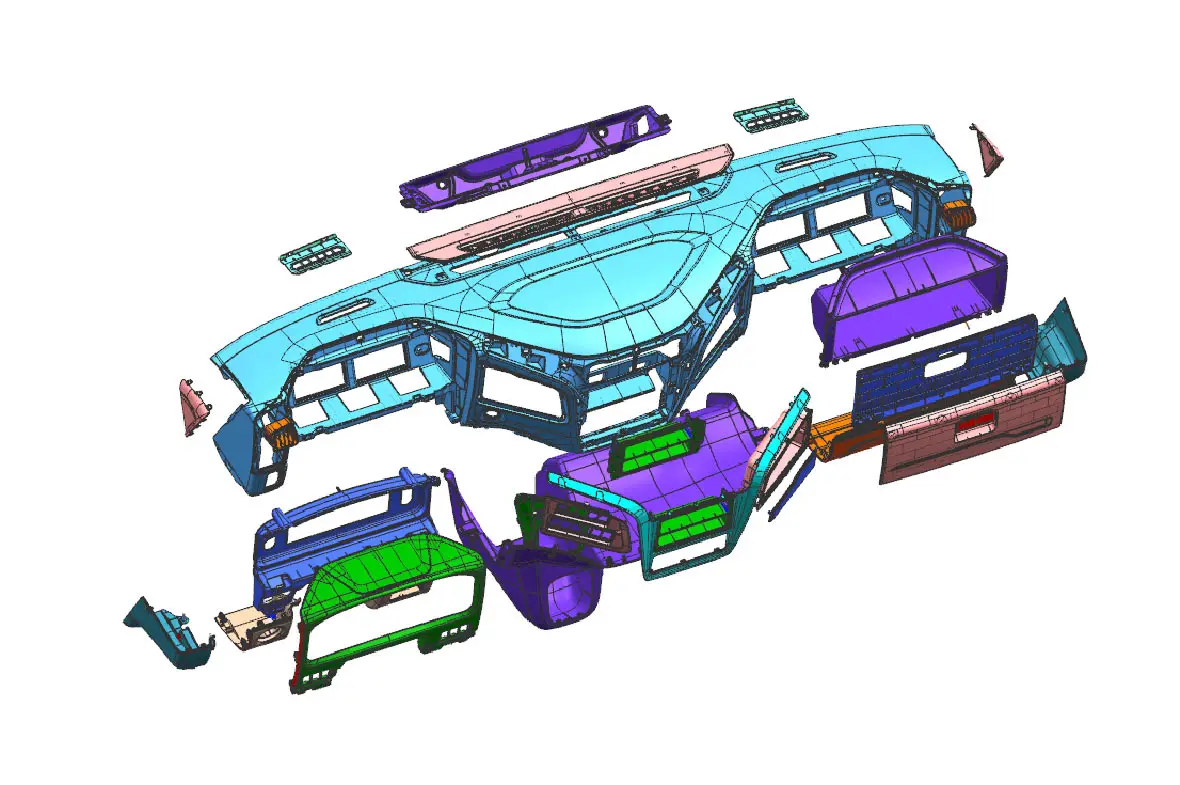

At WOKA, we approach mold construction with a deep sense of gratitude and dedication. Our team of experienced professionals meticulously plans and engineers each mold, considering every detail to achieve optimal performance and precision. From the initial design phase to the final product, we prioritize quality craftsmanship and cutting-edge technologies to create molds that meet the unique requirements of our clients. With our expertise in mold design and engineering, we ensure that every mold constructed by WOKA is a masterpiece of precision and reliability.

Unveiling the Secrets: Key Elements of Mold Construction at WOKA

Material Selection: Thanksgiving for the Perfect Match

Choosing the right materials for mold construction is crucial for achieving superior results. At WOKA, we carefully analyze the specific requirements of each project and select premium-grade materials that offer exceptional durability, heat resistance, and dimensional stability. By partnering with renowned suppliers, we ensure that our molds are built to withstand the rigorous demands of injection molding, ensuring longevity and consistent performance.

Precision CNC Machining: Giving Thanks for Unmatched Accuracy

Precision is the cornerstone of mold construction, and at WOKA, we leave no room for compromise. Our state-of-the-art CNC machining capabilities allow us to achieve unparalleled accuracy and consistency in mold construction. With advanced computer-controlled machines and our skilled technicians, we meticulously carve out intricate cavities, cores, and channels, ensuring that every detail of the mold is precisely crafted to meet the exact specifications of our clients.

Comprehensive Moldflow Analysis: Gratitude for Informed Decision-Making

Moldflow analysis is a powerful tool that enables us to simulate and optimize the mold construction process. At WOKA, we leverage advanced software and expertise to conduct comprehensive Moldflow analysis, providing valuable insights into variables such as temperature, pressure, cooling rates, and material characteristics. By evaluating these factors, we can make informed decisions to enhance the performance, efficiency, and overall quality of the molds we construct. This allows us to identify potential issues and optimize the design to ensure optimal production output and minimize cycle times, all while extending the lifespan of the molds.

Conclusion

At WOKA, mold construction is more than just a process—it’s a testament to our dedication to precision, quality, and customer satisfaction. With gratitude in our hearts, we approach every mold construction project with the utmost care, leveraging our expertise in mold design, precision CNC machining, and comprehensive Moldflow analysis.Partner with WOKA for precision mold construction that lays the foundation for exceptional injection-molded products.